Mineral processing – Milling

Practical Action

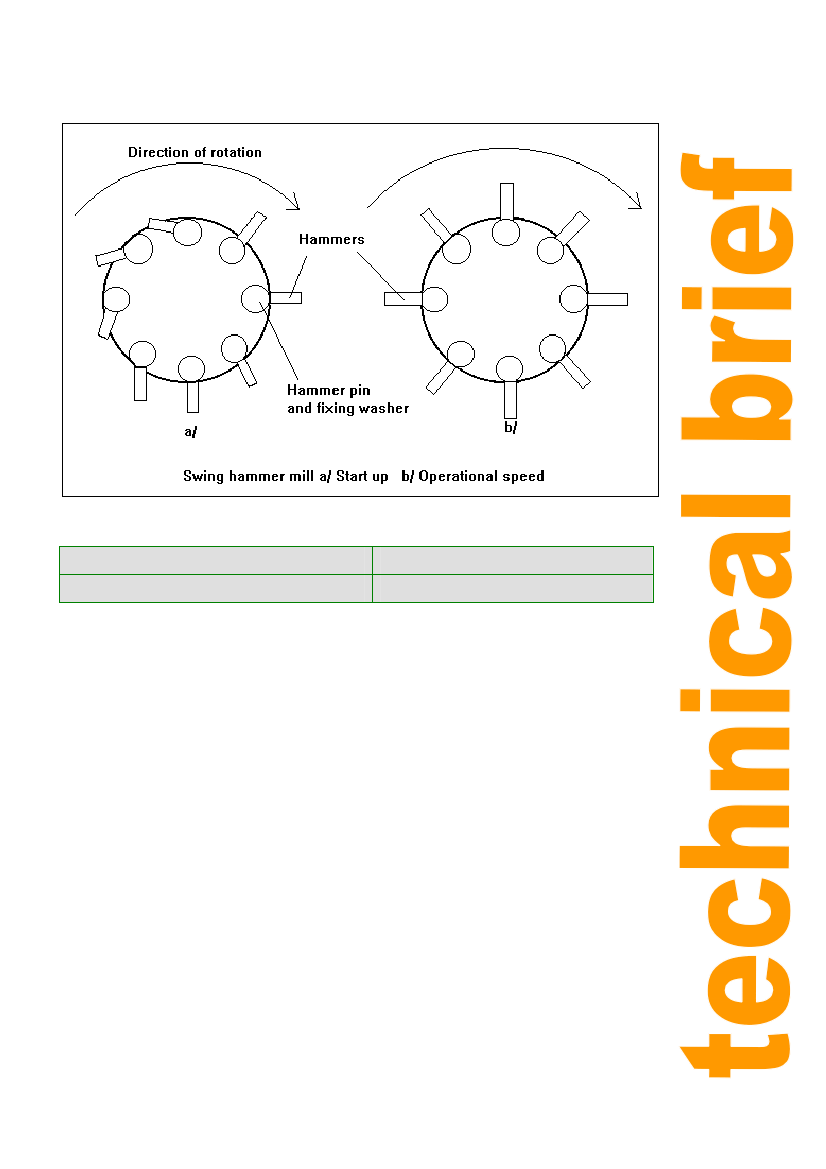

Figure 5: Types of hammer mills

Calcite

Barite

Table 8: Material suitability for hammer mills

Talc

Grain and other food stuffs

Pin, air classifying and turbo mills

Description:

A pin mill comprises two discs, one rotating and one stationary which are fitted with

intermeshing pins set in a concentric pattern. The charge is fed into the centre of the discs

and is broken down as it moves outwards through the pins which are moving at very high speed

- up to 20,000 rpm. The air classifying mill is similar in construction to the pin mill but

incorporates a built-in classifier. This type of mill produces a significant airflow through the

machine to aid with keeping temperature as low as possible. Oversize grains which pass

through the mill have to be recycled. Turbo mills use a similar concept but the rotating disc is

fitted with paddles or bars rather than pins. This rotating disc sits within a cage which is fitted

with grids, screens or breaker plates. The mill is configured in such a way as to produce the

desired particle size.

Characteristics:

Pin mills are capable of very fine grinding without the need for screens and provide a uniform

product size. Air classifying mills are used where the product is temperature sensitive. They

are widely used in the pharmaceutical and fine chemical industries. They are suitable for

relatively soft materials (below Moh 3) and for small quantities of material. Wear on the pins is

significant if used continuously.

8